Picture this: It’s 3 AM, and your CISO’s phone is buzzing with an urgent alert. A sophisticated threat actor has infiltrated your manufacturing facility’s operational technology network, threatening to shut down production lines that generate millions in daily revenue. This isn’t a hypothetical scenario—it’s the harsh reality facing industrial organizations worldwide in 2025.

The convergence of information technology (IT) and operational technology (OT) has created unprecedented opportunities for efficiency and innovation. However, it has also opened critical attack vectors that cybercriminals are increasingly exploiting. Recent industry analysis reveals that cyberattacks on industrial control systems have increased by 87% over the past two years, with the average cost of an OT security incident reaching $4.7 million.

For C-level executives and cybersecurity consultants, understanding cybersecurity in industrial control systems isn’t just about protecting infrastructure—it’s about safeguarding business continuity, regulatory compliance, and competitive advantage. The threat landscape has evolved dramatically, and traditional IT security approaches simply aren’t sufficient for protecting industrial environments.

This comprehensive guide examines the emerging threats reshaping Cybersecurity in Industrial Control Systems in 2025, analyzes recent high-profile attacks, and provides strategic frameworks that executives can implement immediately. You’ll discover actionable best practices for building resilient ICS security programs, navigating complex regulatory requirements, and developing strategic roadmaps that protect both operational integrity and business value.

The stakes have never been higher. Industrial facilities control everything from power grids and water treatment plants to manufacturing lines and chemical processes. A successful cyberattack doesn’t just mean data loss—it can result in physical damage, environmental disasters, and threats to public safety. As we’ll explore, the threat actors targeting these systems in 2025 are more sophisticated, better funded, and increasingly focused on maximum business disruption.

Table of Contents

The Evolving Threat Landscape: 2025’s Most Dangerous Developments

AI-Powered Attack Sophistication

The cybersecurity landscape has fundamentally shifted with the weaponization of artificial intelligence by threat actors. Unlike previous years where attacks relied primarily on known vulnerabilities and social engineering, 2025 has witnessed the emergence of AI-driven reconnaissance and attack automation specifically targeting industrial control systems.

Threat actors are now deploying machine learning algorithms to map industrial networks, identify critical control points, and optimize attack timing for maximum operational disruption. These AI-powered tools can analyze vast amounts of industrial protocol traffic, learning normal operational patterns and identifying the most strategic moments to strike. The result is attacks that are not only more targeted but also significantly harder to detect using traditional security monitoring.

Recent intelligence from the Cybersecurity and Infrastructure Security Agency (CISA) indicates that state-sponsored groups are investing heavily in AI-powered industrial espionage tools. These sophisticated systems can remain dormant within industrial networks for months, continuously learning and mapping critical infrastructure before executing coordinated attacks.

Supply Chain Infiltration at Scale

The industrial supply chain has become the preferred attack vector for advanced persistent threat (APT) groups in 2025. Rather than attempting direct penetration of heavily fortified industrial networks, threat actors are compromising suppliers, vendors, and service providers who have trusted access to target environments.

This trend represents a strategic evolution in industrial cyber warfare. By infiltrating software vendors, equipment manufacturers, and maintenance service providers, attackers can embed malicious code directly into industrial systems during routine updates or maintenance activities. The SolarWinds breach methodology has been refined and weaponized specifically for industrial environments.

Manufacturing executives should be particularly concerned about this development, as it fundamentally challenges traditional perimeter-based security models. When legitimate vendors become unwitting attack vectors, standard security controls become ineffective, requiring entirely new approaches to supply chain risk management.

Protocol-Specific Exploitation Techniques

Industrial control systems rely on specialized communication protocols like MODBUS, DNP3, and Ethernet/IP that were designed for reliability and interoperability rather than security. In 2025, we’re witnessing sophisticated attacks that exploit these protocols’ inherent vulnerabilities in ways that were previously theoretical.

Threat actors are developing protocol-aware malware that can manipulate industrial processes with surgical precision. Unlike broad-spectrum attacks that cause obvious disruption, these new threats can subtly alter production parameters, quality control settings, or safety thresholds in ways that may not be immediately apparent but can cause significant long-term damage.

The emergence of “living off the protocol” techniques means attackers can achieve their objectives using legitimate industrial communication methods, making detection extremely challenging. Security teams trained primarily in traditional IT environments often lack the specialized knowledge needed to identify these subtle but dangerous manipulations of industrial protocols.

High-Profile Case Studies: Strategic Lessons from Recent Attacks

The Colonial Pipeline Analysis: Beyond the Headlines

While many executives are familiar with the Colonial Pipeline incident, the strategic implications extend far beyond the initial ransomware attack headlines. The attack revealed critical vulnerabilities in the interconnected nature of modern industrial infrastructure and highlighted the challenges of rapid incident response in OT environments.

The attackers demonstrated sophisticated understanding of industrial operations, timing their attack to coincide with peak fuel demand periods and leveraging knowledge of emergency shutdown procedures to maximize business disruption. More concerning for executives was the revelation that the operational technology systems were segregated from IT networks, yet the business impact forced operational shutdowns as a precautionary measure.

This case study illustrates a crucial strategic lesson: even when OT networks remain technically secure, the interconnected nature of modern industrial operations means that IT security incidents can still force operational shutdowns. This reality requires executives to rethink traditional IT/OT separation strategies and develop more nuanced incident response capabilities.

The financial implications were staggering, with estimated losses exceeding $90 million in the first week alone. However, the broader economic impact—including supply chain disruptions, consumer panic, and regulatory scrutiny—created cascading effects that lasted months. For C-level executives, this demonstrates the critical importance of considering systemic risk rather than just direct technical vulnerabilities.

Manufacturing Sector Targeting: The Automotive Supply Chain Breach

A sophisticated APT group successfully infiltrated a major automotive supplier’s industrial control systems in late 2024, providing valuable insights into how threat actors are adapting their tactics for manufacturing environments. The attack began with a seemingly routine software update from a trusted vendor, highlighting the supply chain infiltration trends discussed earlier.

What made this breach particularly concerning for executives was the attackers’ strategic patience. Rather than immediately disrupting operations or deploying ransomware, they spent four months mapping the industrial network, identifying critical production lines, and understanding the interdependencies between different manufacturing processes.

The threat actors demonstrated deep understanding of automotive manufacturing workflows, specifically targeting systems that controlled quality assurance processes. By subtly modifying quality control parameters, they could have potentially introduced defects into thousands of vehicles before detection. The attack was discovered only when routine security audits detected unusual network traffic patterns.

This case study emphasizes several critical strategic points for executives. First, the extended dwell time demonstrates that traditional incident response timelines are inadequate for industrial environments. Second, the focus on quality systems rather than production systems shows that threat actors are evolving beyond simple disruption tactics toward more sophisticated business damage strategies.

The breach also highlighted gaps in vendor risk management processes. Despite having robust cybersecurity policies for direct suppliers, the organization had limited visibility into the security practices of sub-tier suppliers and service providers. This created a cascade of vulnerabilities that sophisticated threat actors successfully exploited.

Critical Infrastructure: The Water Treatment Facility Incident

Perhaps most concerning for public safety executives was a 2024 incident involving a municipal water treatment facility that showcased the potential for physical harm from industrial cybersecurity breaches. The attack targeted supervisory control and data acquisition (SCADA) systems responsible for chemical dosing and water quality monitoring.

The threat actors gained initial access through a compromised remote access solution used by maintenance contractors. Once inside the industrial network, they demonstrated sophisticated understanding of water treatment processes, specifically targeting systems that controlled pH levels and disinfection processes. The attack could have potentially contaminated the water supply for over 100,000 residents.

What made this incident particularly instructive for executives was the response complexity. Unlike traditional IT incidents where systems can be immediately isolated or shut down, water treatment operations require continuous monitoring and control to ensure public safety. The incident response team faced the challenging task of securing systems while maintaining essential services.

The breach revealed critical gaps in industrial cybersecurity planning. While the organization had comprehensive enterprise cybersecurity policies, these policies were designed primarily for IT environments and proved inadequate for addressing OT-specific risks and response requirements.

This case study demonstrates the critical importance of developing specialized incident response capabilities for industrial environments. Traditional cybersecurity frameworks must be adapted to address the unique requirements of continuous operations, safety systems, and regulatory compliance in industrial settings.

Strategic Best Practices for Executive Leadership

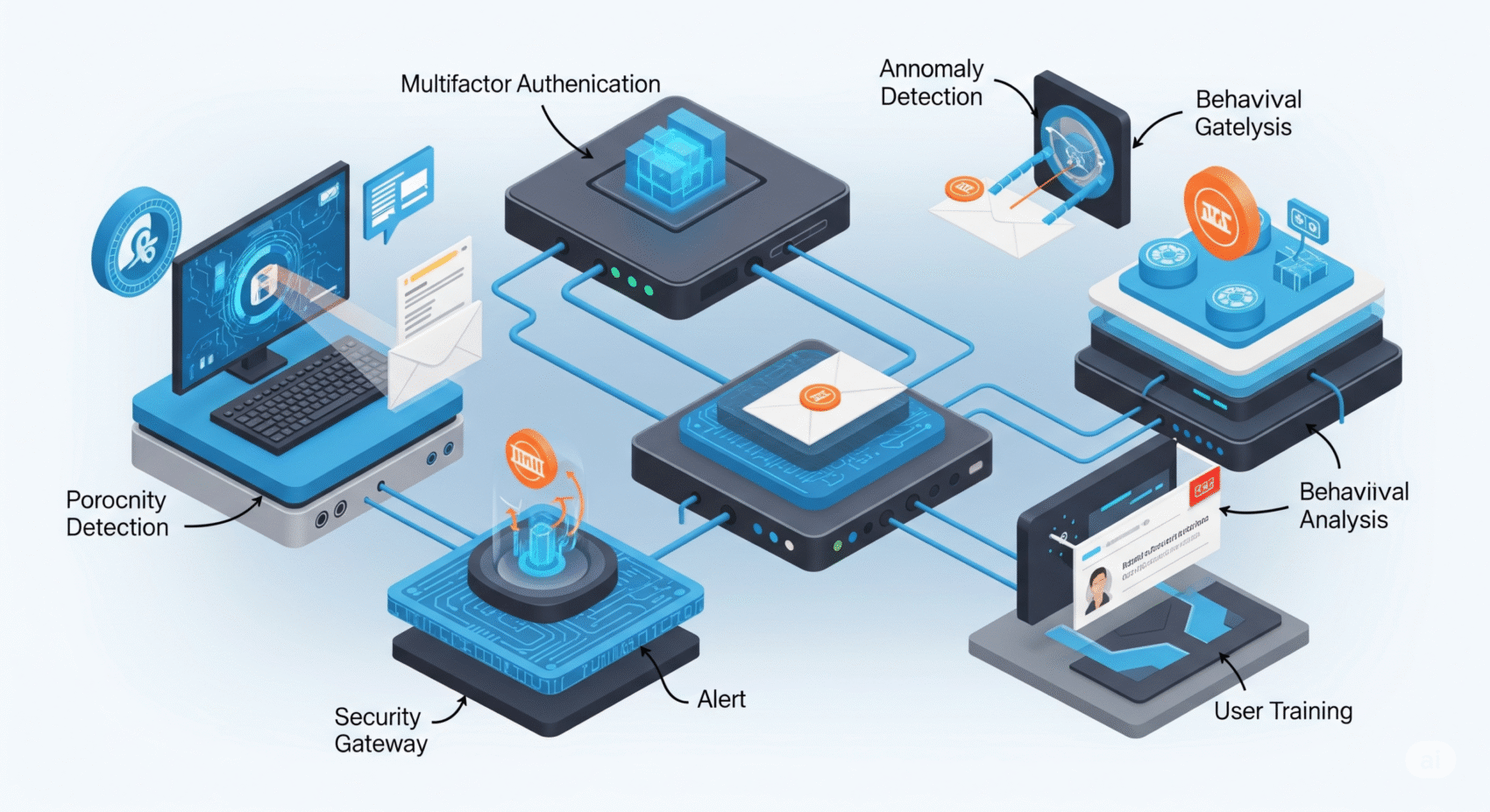

Implementing Zero Trust Architecture in Industrial Environments

The traditional approach of creating air gaps between IT and OT networks is no longer viable in today’s interconnected industrial landscape. Forward-thinking executives are implementing zero trust architecture principles specifically adapted for industrial control systems, but this requires careful strategic planning and execution.

Zero trust for industrial environments differs significantly from traditional IT implementations. The focus shifts from user identity verification to device authentication, protocol validation, and behavioral monitoring of industrial communications. This approach recognizes that industrial systems often operate with service accounts and automated processes that don’t fit traditional user-based security models.

Successful implementation requires a phased approach that prioritizes critical systems while maintaining operational continuity. Executives should focus on creating micro-segments around the most critical industrial processes first, then gradually expanding coverage as teams develop expertise and confidence with the new architecture.

The strategic benefit of zero trust in industrial environments extends beyond security improvement. Organizations implementing these principles report better visibility into industrial operations, improved compliance documentation, and enhanced ability to detect both security threats and operational anomalies.

However, executives must be prepared for significant organizational change management challenges. Industrial teams accustomed to relatively open internal networks may resist new authentication and authorization requirements. Success requires clear communication about business benefits and comprehensive training programs for operational staff.

Building Threat Intelligence Capabilities Specific to Industrial Sectors

Generic threat intelligence feeds provide limited value for protecting industrial control systems. Executives should prioritize developing sector-specific threat intelligence capabilities that focus on the unique risks facing their industry and operational technology stack.

This specialized approach requires partnerships with industry-specific information sharing organizations, such as sector-specific Information Sharing and Analysis Centers (ISACs). These organizations provide targeted intelligence about threat actors specifically focused on industrial sectors, including tactics, techniques, and procedures (TTPs) adapted for industrial environments.

Effective industrial threat intelligence programs integrate multiple data sources, including operational technology vendors, government agencies, and peer organizations within the same industrial sector. The goal is creating actionable intelligence that can inform both strategic security planning and tactical incident response decisions.

For executives, the strategic value of specialized threat intelligence extends beyond immediate security benefits. Organizations with mature industrial threat intelligence capabilities report improved regulatory compliance, better vendor risk management, and enhanced ability to make informed cybersecurity investment decisions.

Implementation requires dedicated resources and expertise that many organizations lack internally. Successful executives often begin with external consulting partnerships while building internal capabilities over time. The key is ensuring that threat intelligence programs are closely integrated with both operational teams and executive decision-making processes.

Developing OT-Aware Security Operations Centers

Traditional security operations centers (SOCs) designed for IT environments often struggle to effectively monitor and respond to threats in industrial control system environments. The protocols, normal behaviors, and response requirements are fundamentally different, requiring specialized capabilities and expertise.

OT-aware SOCs require security analysts who understand both cybersecurity principles and industrial operations. This means investing in cross-training programs or hiring personnel with both skill sets. The scarcity of these specialized professionals makes this a significant strategic challenge for many organizations.

The technology stack for OT security monitoring differs substantially from traditional IT security tools. Industrial protocol analyzers, SCADA-specific intrusion detection systems, and specialized forensics tools designed for operational technology environments are essential components that many traditional SOCs lack.

Perhaps most critically, OT-aware SOCs must be integrated with operational teams and emergency response procedures. Unlike IT incidents where systems can be immediately isolated, industrial security incidents often require coordination with safety systems, regulatory agencies, and emergency responders.

Executives should consider hybrid approaches that leverage existing SOC investments while adding specialized OT capabilities. This might include dedicated OT security analysts within existing SOCs, partnerships with specialized industrial cybersecurity providers, or development of separate but coordinated OT security operations capabilities.

Implementing Continuous Risk Assessment Frameworks

The dynamic nature of industrial environments requires continuous rather than periodic risk assessment approaches. Equipment changes, software updates, operational modifications, and evolving threat landscapes create constantly shifting risk profiles that traditional annual assessments cannot adequately address.

Effective continuous risk assessment frameworks integrate multiple data sources, including asset inventory systems, vulnerability scanners adapted for industrial environments, threat intelligence feeds, and operational change management processes. The goal is creating real-time visibility into the evolving risk landscape.

These frameworks must account for the unique characteristics of industrial systems, including legacy equipment that cannot be easily updated, safety-critical processes that cannot be interrupted for security testing, and complex interdependencies between different operational systems.

For executives, continuous risk assessment provides strategic benefits beyond security improvement. Organizations implementing these approaches report better regulatory compliance documentation, improved insurance risk profiles, and enhanced ability to make data-driven cybersecurity investment decisions.

Implementation requires significant organizational change, particularly in industrial environments where change management processes are often focused on safety rather than security considerations. Success requires integration with existing operational procedures and clear communication about business benefits to operational staff.

Regulatory Compliance Framework & Upcoming Requirements

Understanding the Evolving Regulatory Landscape

The regulatory environment for industrial cybersecurity is experiencing unprecedented change in 2025, with new requirements emerging across multiple sectors and jurisdictions. For executives, staying ahead of these evolving requirements is crucial for avoiding compliance penalties and maintaining competitive advantage.

The National Institute of Standards and Technology (NIST) has updated its Cybersecurity Framework specifically to address industrial control systems, incorporating lessons learned from recent high-profile incidents. These updates emphasize the importance of continuous monitoring, supply chain risk management, and integration with safety management systems.

Transportation Security Administration (TSA) requirements for pipeline and rail operators have expanded significantly, moving beyond basic cybersecurity measures to mandate specific technical controls and reporting requirements. These regulations require organizations to implement comprehensive cybersecurity programs that address both IT and OT environments.

The European Union’s Network and Information Systems (NIS2) Directive has created new requirements for industrial organizations operating in European markets, with significant financial penalties for non-compliance. These requirements extend beyond traditional cybersecurity measures to include supply chain risk management, incident reporting, and executive accountability provisions.

For multinational organizations, the challenge of managing compliance across multiple regulatory frameworks requires strategic coordination and comprehensive documentation systems. The cost of non-compliance extends beyond financial penalties to include reputational damage, operational restrictions, and competitive disadvantage.

Sector-Specific Compliance Requirements

Different industrial sectors face varying regulatory requirements that executives must understand and address through their cybersecurity programs. Manufacturing organizations must comply with export control regulations that have cybersecurity implications, while energy sector companies face specialized requirements from the Federal Energy Regulatory Commission (FERC) and regional reliability organizations.

Water and wastewater utilities operate under America’s Water Infrastructure Act requirements that mandate cybersecurity risk assessments and emergency response plans. These requirements emphasize the integration of cybersecurity with physical security and emergency management capabilities.

Chemical manufacturers must address both Cybersecurity and Infrastructure Security Agency (CISA) guidelines and Environmental Protection Agency (EPA) requirements that link cybersecurity with environmental protection and public safety obligations. The regulatory complexity requires specialized expertise and coordinated compliance management approaches.

Healthcare organizations operating industrial systems face unique challenges balancing patient safety requirements with cybersecurity obligations. The intersection of HIPAA privacy requirements, FDA medical device regulations, and industrial control system security creates complex compliance scenarios that require careful strategic planning.

For executives managing organizations that operate across multiple sectors, developing comprehensive compliance management frameworks that address overlapping and sometimes conflicting requirements is essential. This often requires legal expertise, regulatory affairs specialists, and close coordination with government relations teams.

Preparing for Future Regulatory Changes

The regulatory landscape for industrial cybersecurity will continue evolving rapidly, with new requirements emerging in response to evolving threats and high-profile incidents. Executives must develop strategic approaches that not only address current requirements but also prepare for anticipated future changes.

Government agencies are increasingly focusing on supply chain cybersecurity requirements that will extend compliance obligations to vendors, suppliers, and service providers. Organizations should begin assessing and improving their supply chain risk management capabilities in anticipation of these requirements.

International harmonization efforts are creating new compliance challenges and opportunities for multinational organizations. While standardized requirements may reduce compliance complexity over time, the transition period requires careful management of multiple regulatory frameworks.

The trend toward executive accountability in cybersecurity regulations means that C-level executives face personal liability for cybersecurity failures. This reality requires not only robust cybersecurity programs but also comprehensive documentation systems that demonstrate due diligence and good faith efforts to address cybersecurity risks.

Organizations should develop regulatory monitoring capabilities that track emerging requirements across relevant jurisdictions and sectors. This proactive approach enables strategic planning and budget allocation while avoiding the costs and risks associated with reactive compliance management.

Building Your ICS Security Roadmap: Executive Action Plan

Phase 1: Strategic Assessment and Foundation Building (Months 1-6)

The foundation of any successful industrial cybersecurity program begins with comprehensive assessment of current capabilities, risk exposure, and organizational readiness. This initial phase requires executive sponsorship and cross-functional coordination between IT, OT, and business leadership teams.

Begin with asset inventory and network mapping activities that provide complete visibility into industrial control systems, network architectures, and interdependencies. Many organizations discover they have limited understanding of their OT environment, including legacy systems, network connections, and critical dependencies that weren’t previously documented.

Conduct risk assessments that specifically address industrial cybersecurity threats, using frameworks designed for operational technology environments rather than adapting IT-focused methodologies. These assessments should evaluate both cyber and physical risks, considering the potential for cyberattacks to cause safety incidents, environmental damage, or business disruption.

Establish governance structures that integrate cybersecurity decision-making with operational management and business strategy processes. This includes defining roles and responsibilities, establishing communication protocols, and creating accountability frameworks that ensure cybersecurity considerations are integrated into business decisions.

Develop baseline security policies and procedures specifically adapted for industrial environments, recognizing the unique requirements of continuous operations, safety systems, and regulatory compliance. These policies should address both technical controls and organizational processes, including incident response, change management, and vendor risk management.

The strategic goal of this phase is creating a solid foundation for long-term cybersecurity improvement while addressing the most critical immediate risks. Success requires balancing the need for comprehensive understanding with the urgency of implementing basic security controls.

Phase 2: Implementation of Core Security Controls (Months 6-18)

With a solid foundation in place, focus shifts to implementing core security controls specifically designed for industrial control system environments. This phase requires careful coordination with operational teams to ensure that security improvements don’t disrupt critical business processes.

Network segmentation should be the highest priority, creating logical and physical separation between different industrial networks and between IT and OT environments. However, modern industrial operations often require some level of integration, so segmentation strategies must balance security benefits with operational requirements.

Implement monitoring and detection capabilities designed specifically for industrial protocols and operational technology systems. Traditional IT security tools often struggle to understand industrial communications, requiring specialized solutions that can parse industrial protocols and identify anomalous behaviors specific to OT environments.

Deploy endpoint protection solutions adapted for industrial control systems, recognizing that traditional antivirus software may not be compatible with specialized industrial hardware and software. This often requires working closely with industrial system vendors to identify compatible security solutions.

Establish identity and access management controls that address the unique characteristics of industrial environments, including service accounts, shared credentials, and systems that require continuous operation. These controls must balance security requirements with operational needs and regulatory compliance obligations.

Develop incident response capabilities specifically adapted for industrial environments, including procedures that address the unique challenges of investigating and responding to incidents in systems that cannot be easily shut down or isolated. This includes coordination with safety systems, regulatory agencies, and emergency responders.

Phase 3: Advanced Capabilities and Continuous Improvement (Months 18+)

The final phase focuses on developing advanced cybersecurity capabilities that provide strategic competitive advantage and position the organization for future challenges. This includes emerging technologies, threat intelligence capabilities, and organizational maturity improvements.

Implement threat intelligence programs that provide actionable information about threat actors specifically targeting industrial control systems. This requires partnerships with government agencies, industry organizations, and specialized threat intelligence providers who understand industrial cybersecurity threats.

Develop security orchestration and automated response capabilities that can address the high-speed, high-volume threat environment while maintaining the reliability and safety requirements of industrial operations. Automation must be carefully implemented to avoid interfering with critical processes or safety systems.

Establish continuous compliance monitoring and reporting capabilities that provide real-time visibility into regulatory compliance status across multiple frameworks and jurisdictions. This is particularly important for organizations operating in highly regulated industries or multiple geographic markets.

Build strategic partnerships with cybersecurity providers, technology vendors, and research organizations to stay ahead of evolving threats and emerging technologies. These relationships provide access to specialized expertise and early insight into new security capabilities.

The ultimate goal is creating a mature cybersecurity program that not only protects industrial operations but also provides strategic business value through improved operational visibility, enhanced regulatory compliance, and reduced business risk.

Integration with Business Continuity and Risk Management

Aligning Cybersecurity with Business Objectives

Industrial cybersecurity programs must be closely aligned with broader business objectives to ensure sustainable executive support and appropriate resource allocation. This alignment requires demonstrating clear connections between cybersecurity investments and business value, including operational efficiency, competitive advantage, and risk reduction.

Successful cybersecurity programs integrate with existing business continuity planning processes, ensuring that cybersecurity considerations are incorporated into broader risk management frameworks. This includes quantifying the potential business impact of cyber incidents and developing response strategies that protect both operational integrity and business value.

The emergence of cyber insurance as a critical risk management tool requires executives to understand how industrial cybersecurity programs affect insurance coverage and premiums. Many insurers are developing specialized policies for industrial cyber risks, but coverage often depends on demonstrating mature cybersecurity capabilities.

For manufacturing organizations, cybersecurity considerations must be integrated into product quality and safety management systems. Cyberattacks that compromise quality control systems can create product liability risks that extend far beyond immediate operational disruption.

The strategic value of integrated cybersecurity and business planning extends beyond risk reduction to include improved operational visibility, enhanced regulatory compliance capabilities, and better vendor risk management. Organizations that successfully integrate these capabilities report competitive advantages in areas ranging from operational efficiency to customer confidence.

Measuring Success and Return on Investment

Establishing appropriate metrics for industrial cybersecurity programs requires balancing traditional security metrics with operational and business performance indicators. This comprehensive approach provides executives with the information needed to make informed investment decisions and demonstrate program value to stakeholders.

Traditional security metrics such as vulnerability counts, incident response times, and compliance scores provide important baseline information but don’t fully capture the value of industrial cybersecurity programs. These metrics must be supplemented with operational indicators such as system availability, production efficiency, and quality metrics.

Business impact metrics should include both direct costs avoided (such as incident response expenses and regulatory penalties) and indirect benefits (such as improved customer confidence, enhanced vendor relationships, and reduced insurance premiums). Quantifying these benefits often requires collaboration with finance, operations, and business development teams.

Developing comprehensive cybersecurity dashboards that integrate security, operational, and business metrics provides executives with holistic visibility into program performance and business impact. These dashboards should be designed for different audiences, including technical teams, operational management, and executive leadership.

The challenge of measuring return on investment for cybersecurity programs is particularly acute in industrial environments where the cost of major incidents can be catastrophic but the probability of occurrence may seem low. Developing risk-adjusted ROI calculations that account for both high-impact, low-probability events and ongoing operational benefits provides a more complete picture of program value.

Preparing for Tomorrow’s Threats: Strategic Recommendations

Emerging Technologies and Future Risks

The industrial cybersecurity threat landscape will continue evolving rapidly, driven by technological advancement, geopolitical tensions, and the increasing sophistication of threat actors. Executives must develop strategic approaches that not only address current risks but also prepare for future challenges.

The integration of artificial intelligence and machine learning into industrial operations creates new attack surfaces and vulnerabilities that traditional security approaches cannot address. As industrial systems become more autonomous and interconnected, the potential impact of successful cyberattacks will continue to increase.

Quantum computing developments pose long-term risks to current cryptographic protections used in industrial control systems. While practical quantum computers capable of breaking current encryption standards may still be years away, organizations should begin planning for post-quantum cryptography implementations.

The expansion of industrial Internet of Things (IoT) devices creates vast new attack surfaces that are often difficult to monitor and protect using traditional security tools. As industrial operations become increasingly sensor-driven and data-dependent, securing these distributed systems becomes critical for overall cybersecurity posture.

Climate change and extreme weather events are creating new cybersecurity challenges as organizations implement resilience and adaptation strategies that rely heavily on digital technologies. The intersection of climate resilience and cybersecurity requires strategic planning that addresses both physical and digital risks.

Building Organizational Resilience

Beyond technical security measures, building organizational resilience requires developing cultural, procedural, and strategic capabilities that enable organizations to adapt and respond effectively to evolving cybersecurity challenges.

This includes developing cross-functional expertise that bridges traditional IT/OT boundaries, creating teams that understand both cybersecurity principles and industrial operations. The scarcity of professionals with these combined skill sets makes talent development and retention critical strategic priorities.

Organizational resilience also requires developing strategic partnerships and relationships that provide access to specialized expertise, threat intelligence, and incident response capabilities. No organization can develop all necessary capabilities internally, making strategic partnerships essential for comprehensive cybersecurity programs.

The ability to learn and adapt quickly from both successful attacks and near-miss incidents provides competitive advantage in the rapidly evolving cybersecurity landscape. This requires developing organizational cultures that prioritize continuous learning, knowledge sharing, and proactive risk management.

For executives, building organizational resilience means creating systems and processes that can function effectively even when facing novel threats or unprecedented challenges. This includes redundancy in critical capabilities, cross-training of personnel, and decision-making frameworks that can function under pressure.

Conclusion: Securing Industrial Operations in an Uncertain Future

The cybersecurity challenges facing industrial control systems in 2025 represent a fundamental shift from traditional IT security concerns to complex, multifaceted risks that threaten not only data and systems but also physical safety, business continuity, and competitive viability. For C-level executives and cybersecurity consultants, addressing these challenges requires strategic thinking that goes far beyond traditional security frameworks.

The emerging threat landscape we’ve examined—from AI-powered attacks to sophisticated supply chain infiltrations—demands response strategies that are equally sophisticated and strategically aligned with business objectives. The case studies analyzed demonstrate that successful attacks on industrial systems create cascading effects that extend far beyond immediate technical impacts to affect entire industries, communities, and economic sectors.

The strategic best practices outlined in this guide provide a roadmap for building comprehensive cybersecurity programs that protect industrial operations while supporting business growth and innovation. However, success requires more than technical implementation—it demands organizational transformation, cultural change, and sustained executive commitment.

The regulatory compliance landscape will continue evolving rapidly, requiring proactive strategic planning rather than reactive compliance management. Organizations that view regulatory requirements as minimum standards rather than ultimate goals will be better positioned to address both current obligations and future requirements.

Perhaps most importantly, the integration of cybersecurity considerations with broader business strategy, operational planning, and risk management creates competitive advantages that extend beyond security benefits. Organizations that successfully implement comprehensive industrial cybersecurity programs report improved operational visibility, enhanced customer confidence, better vendor relationships, and reduced overall business risk.

The path forward requires sustained investment, strategic partnership, and organizational commitment. The threats facing industrial control systems will continue evolving, but organizations that implement comprehensive, strategically aligned cybersecurity programs will be prepared to address both current challenges and future risks.

For executives reading this guide, the time for action is now. The threat actors targeting industrial systems are not waiting for perfect solutions or complete readiness—they are actively exploiting vulnerabilities and developing new attack methods every day. The question is not whether your organization will face cybersecurity challenges, but whether you will be prepared when they arrive.

The frameworks, strategies, and recommendations provided here offer a comprehensive foundation for building industrial cybersecurity capabilities that protect not only technical systems but also business value, competitive advantage, and stakeholder confidence. The investment required is significant, but the cost of inaction is potentially catastrophic.

As we move deeper into 2025 and beyond, cybersecurity in industrial control systems will become increasingly critical for business success, regulatory compliance, and competitive survival. Organizations that recognize this reality and take decisive action will be positioned for success in an uncertain but opportunity-rich future.

The industrial cybersecurity landscape demands executive leadership, strategic vision, and sustained commitment. The tools and knowledge exist to build effective protection—what’s needed now is the will to act and the wisdom to act strategically. Your organization’s future depends on the decisions you make today.

Frequently Asked Questions (FAQs)

Q: How do Cybersecurity in Industrial Control Systems requirements differ from traditional IT security?

Industrial control systems operate in environments where availability and reliability are often more critical than confidentiality. Unlike traditional IT systems that can be taken offline for security updates, industrial systems must maintain continuous operation to ensure safety and business continuity. This requires specialized security approaches that balance protection with operational requirements, including different incident response procedures and risk assessment methodologies.

Q: What are the most critical first steps for executives beginning an industrial cybersecurity program?

Start with comprehensive asset inventory and risk assessment specifically designed for operational technology environments. Many organizations discover they have limited visibility into their industrial systems during this process. Establish clear governance structures that integrate cybersecurity with operational management, and prioritize network segmentation to create baseline protection while building more advanced capabilities.

Q: How can organizations balance cybersecurity investments with operational budget constraints?

Focus on risk-based prioritization that addresses the most critical vulnerabilities and highest-impact scenarios first. Integrate cybersecurity investments with planned operational technology upgrades and modernization projects to maximize efficiency. Consider the total cost of ownership, including potential incident costs, regulatory penalties, and business disruption, when evaluating investment options.

Q: What role should boards and executive leadership play in industrial cybersecurity oversight?

Boards should establish clear cybersecurity risk appetite statements and ensure regular reporting on both cybersecurity posture and business risk implications. Executive leadership must champion cross-functional coordination between IT, OT, and business teams, ensuring that cybersecurity considerations are integrated into strategic planning and operational decision-making processes.

Q: How can organizations address the shortage of qualified industrial cybersecurity professionals?

Develop comprehensive training programs that cross-train existing IT security professionals in operational technology and industrial operations staff in cybersecurity principles. Establish strategic partnerships with specialized consulting firms and managed security service providers. Invest in continuous education and professional development to retain existing talent while building internal capabilities over time.

Q: What are the key considerations for managing cybersecurity during mergers and acquisitions?

Conduct thorough cybersecurity due diligence that specifically addresses operational technology systems, including asset inventory, risk assessment, and compliance status evaluation. Develop integration plans that address both IT and OT cybersecurity concerns, and ensure that cybersecurity considerations are integrated into post-merger integration planning from the beginning rather than being treated as an afterthought.

Q: How should organizations prepare for future regulatory requirements in industrial cybersecurity?

Establish regulatory monitoring capabilities that track emerging requirements across relevant jurisdictions and industries. Implement cybersecurity programs that exceed current minimum requirements, focusing on comprehensive risk management and continuous improvement rather than mere compliance. Develop documentation and reporting systems that can adapt to changing regulatory requirements while demonstrating consistent due diligence efforts.

This work has an elegant simplicity to it, yet it holds layers of depth beneath the surface.